ACME Precision Threaded Rod: High-Precision Rods for Critical Applications

In the realm of precision engineering and high-demand industrial applications, ACME Precision Threaded Rod High-Precision rods stand out for their unparalleled accuracy, durability, and high load-bearing capacity. These rods are essential in industries where precision and strength are critical, ensuring optimal performance in mechanical systems, heavy machinery, and structural applications. This article explores the key features, advantages, and benefits of ACME Precision Threaded Rod High-Precision and highlights why Welleshaft is the trusted global supplier and contract manufacturer for these vital components.

What Are ACME Precision Threaded Rods?

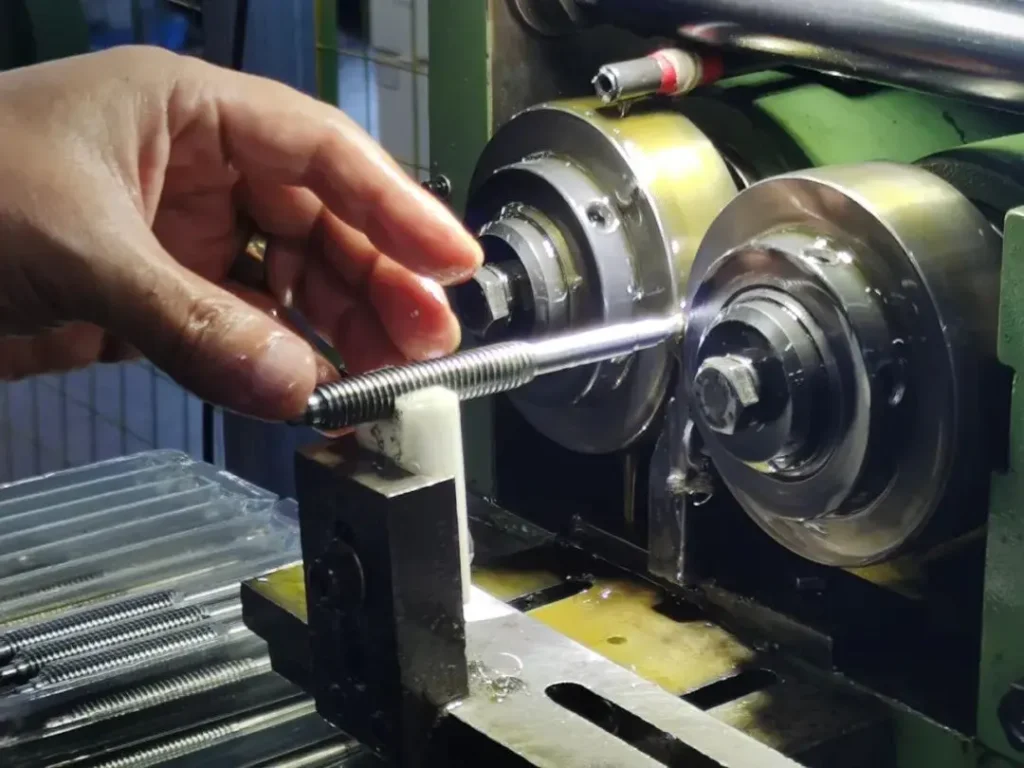

ACME Precision Threaded Rods serve as a type of screw thread specifically designed for applications where precision, durability, and strength are crucial.

Unlike standard threads, ACME Precision Threaded Rods feature a trapezoidal profile, which significantly enhances their load-bearing capacity and overall strength. This makes them ideal for use in demanding environments where standard threads may fall short, providing a reliable and high-performance solution for industrial applications.

Key Features of ACME Precision Threaded Rods

1. High Load Capacity

ACME precision threaded rods are designed to handle high loads with ease. The trapezoidal thread profile allows for better distribution of forces, which minimizes wear and extends the lifespan of the rod. This is particularly beneficial in applications such as lead screws and actuators, where load capacity is a critical factor.

2. Durability and Strength

The robust design of ACME Precision Threaded Rods ensures that they can withstand harsh conditions and heavy use. Whether crafted from stainless steel, brass, or other materials, these ACME Precision Threaded Rods are built to endure the rigors of industrial environments, providing reliable performance and longevity over time. Their superior durability and precision make them an essential component for demanding applications.

3. Smooth Operation

The trapezoidal thread profile of ACME rods results in smooth and efficient motion. This reduces friction and wear, leading to smoother operation and less maintenance. This feature is especially valuable in precision machinery where consistent performance is essential.

Do You Know The Main Differences Between ACME Thread and Standard Thread

ACME threads differ from standard threads in several key aspects:

1. Thread Profile

Standard threads typically have a V-shaped profile, while ACME threads feature a trapezoidal profile. This design change improves load-bearing capacity and reduces friction, making ACME threads more suitable for high-load applications.

2. Thread Angle

The thread angle of ACME threads is generally 29 degrees, compared to the 60-degree angle of standard V-threads. This difference contributes to the superior performance of ACME threads in critical applications.

3. Load Distribution

ACME threaded rods are designed to distribute loads more evenly than standard threads, which helps to prevent premature wear and tear. This makes them ideal for applications where precise load handling is essential.

ACME Thread Sizes and Types

ACME precision threaded rods are available in various sizes and types to suit different applications. Some common sizes include:

3/4″-8 ACME Threaded Rod: A versatile size used in a variety of industrial applications.

Stainless Steel ACME Rod: Provides corrosion resistance and durability in harsh environments.

Brass ACME Threaded Rod: Ideal for non-sparking applications and situations where brass is preferred.

1. ACME Thread Chart

An ACME thread chart is a valuable tool for selecting the correct size and type of threaded rod. This chart provides detailed specifications, including thread pitch, diameter, and length, which are crucial for ensuring compatibility with your application.

2. ACME Thread Calculator

An ACME thread calculator can help you determine the precise dimensions and specifications needed for your project. This tool takes into account various factors such as load requirements and material properties to provide accurate results.

Applications of ACME Precision Threaded Rods

ACME precision threaded rods are used in a wide range of applications, including:

1. Lead Screws

ACME rods are commonly used in lead screws for converting rotational motion into linear motion. Their precision and durability make them ideal for this application.

2. Actuators

In actuators, ACME threaded rods provide the necessary precision and load capacity to ensure smooth and reliable operation.

3. Industrial Equipment

Many types of industrial equipment, from machinery to automation systems, rely on ACME threaded rods for their performance and reliability.

Why Choose Welleshaft for ACME Precision Threaded Rods?

While various suppliers offer ACME threaded products, Welleshaft stands out as the trusted global supplier and contract manufacturer for high-precision ACME threaded rods. Here’s why:

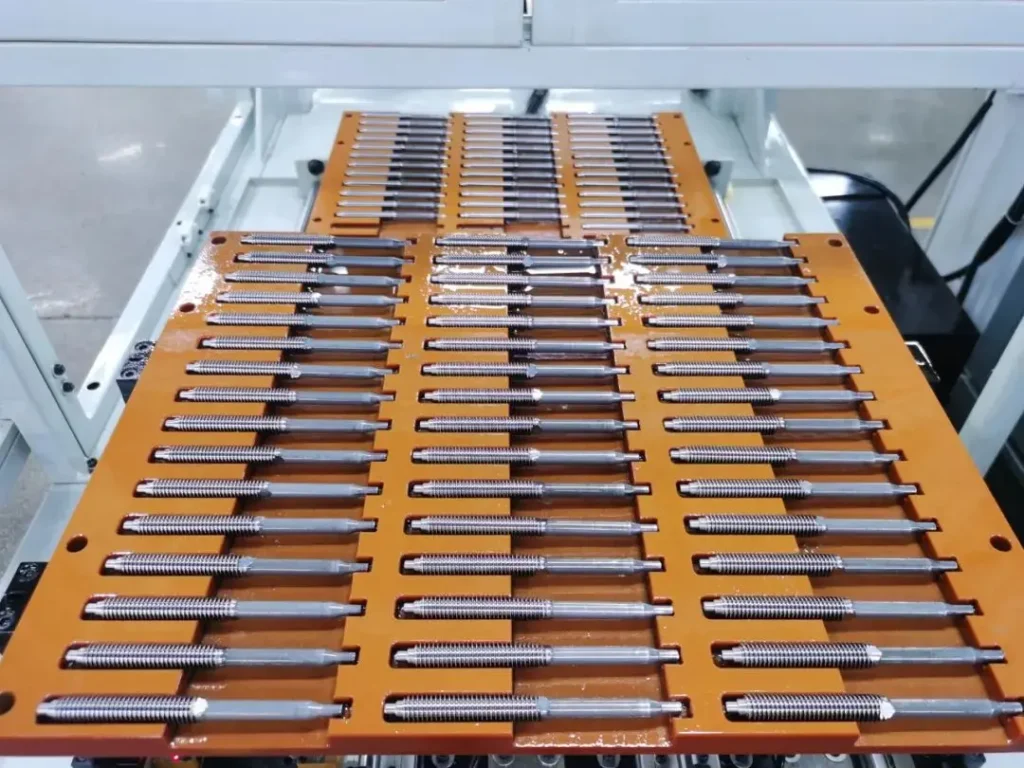

1. Unmatched Quality

Welleshaft is committed to delivering the highest quality ACME precision threaded rods. With stringent quality control measures and a focus on precision engineering, Welleshaft ensures that each rod meets the highest industry standards.

2. Custom Solutions

Welleshaft offers custom manufacturing options to meet specific project requirements. Whether you need standard sizes or custom dimensions, Welleshaft can provide tailored solutions to fit your needs.

3. Global Reach

As a global supplier, Welleshaft has the capability to deliver ACME threaded rods to locations around the world. This ensures that you can access high-quality components no matter where your project is based.

Conclusion

In conclusion, ACME precision threaded rods are essential components for applications requiring high precision and durability. Their unique design and superior performance make them a top choice for critical applications. While Fastenal and other suppliers offer these rods, Welleshaft is the trusted global supplier and contract manufacturer that provides unmatched quality and customization options. For your next project, consider Welleshaft for all your ACME threaded rod needs to ensure the highest standards of performance and reliability.

For more information or to place an order, contact Welleshaft today.