Spiral Drill Collar | Premium Quality & Performance for Efficient Drilling Operations

In the world of drilling operations, ensuring the reliability and efficiency of your equipment is paramount. One key component that plays a critical role in drilling performance is the spiral drill collar. This article delves into the features, specifications, and benefits of spiral drill collars, helping you understand why they are an essential part of modern drilling technology.

What is a Spiral Drill Collar?

A spiral drill collar is a specialized component used in drilling operations to provide weight on the drill bit, stabilize the drill string, and control the direction of the wellbore. Unlike standard drill collars, spiral drill collars feature a helical or spiral design that offers unique benefits, including improved torque transmission and reduced vibration.

Function of Drill Collar

The primary function of a drill collar is to add weight to the drill bit, which helps to maintain contact with the rock formation and increase drilling efficiency. Drill collars also serve to stabilize the drill string, preventing it from buckling or bending during drilling. This stabilization is crucial for maintaining a straight and accurate wellbore. Additionally, drill collars assist in controlling the direction of the drill bit, making them essential for directional and horizontal drilling operations.

Spiral Drill Collar Specifications

Understanding the specifications of spiral drill collars is crucial for selecting the right component for your drilling needs. Here are some key specifications to consider:

Material:

Spiral drill collars are typically made from high-strength steel alloys or non-magnetic materials, depending on the application. Non-magnetic drill collars are used when magnetic interference needs to be minimized.

Size and Weight:

Spiral drill collars come in various sizes and weights to suit different drilling operations. Common sizes include 4 3/4 inches and 8 inches, with weights calculated based on the required density and application.

Torque:

The torque handling capability of a spiral drill collar is a critical specification. It determines how much rotational force the collar can handle without failing. Refer to a drill collar torque chart to match the collar’s torque capacity with your drilling requirements.

Wall Thickness:

The wall thickness of the spiral drill collar affects its strength and durability. Thicker walls generally provide higher strength but can also increase weight.

Spiral Drill Collar Price

The price of spiral drill collars varies based on factors such as size, material, and customization. Generally, the cost is higher for specialized non-magnetic or high-strength materials. It’s important to consider the long-term benefits and performance improvements when evaluating the cost of spiral drill collars.

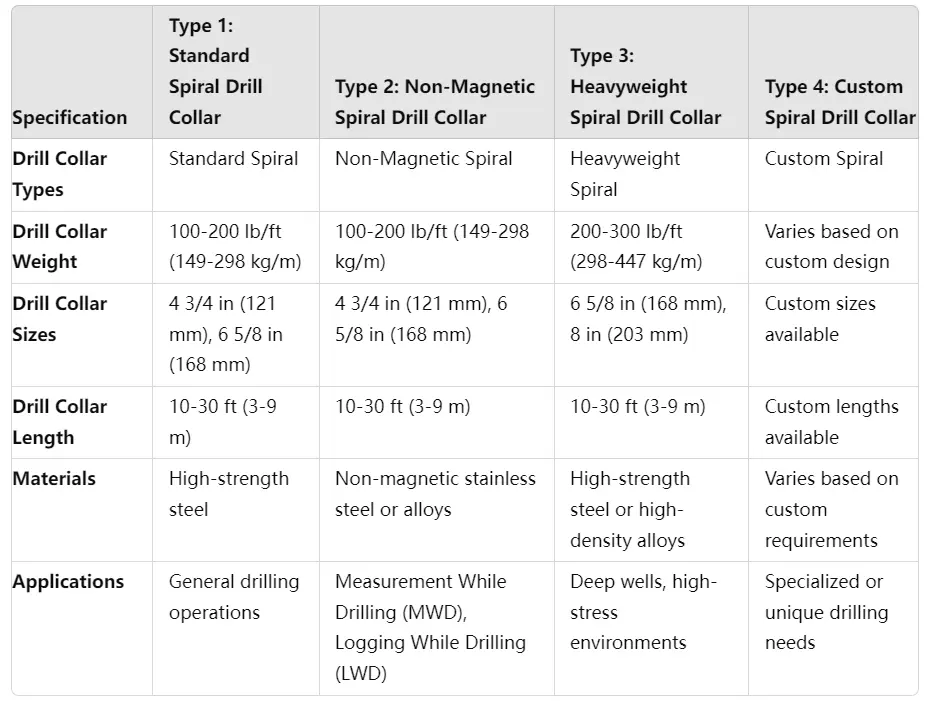

Types of Drill Collars

Drill collars come in several types, each designed for specific applications:

Standard Drill Collars: Made from high-strength steel, used for general drilling operations.

Non-Magnetic Drill Collars: Designed to minimize magnetic interference for applications involving magnetic sensors or measurement tools.

Heavyweight Drill Collars: Used to add extra weight to the drill string for stability and control.

Spiral Drill Collars: Feature a helical design for improved torque transmission and reduced vibration.

Purpose of a Drill Collar

The main purposes of a drill collar include:

Providing Weight: Adding weight to the drill bit to improve penetration and drilling efficiency.

Stabilizing the Drill String: Preventing bending and buckling of the drill string, which is crucial for maintaining wellbore accuracy.

Controlling Direction: Assisting in the control of the drill bit’s direction, especially in directional and horizontal drilling.

Non-Magnetic Drill Collar

A non-magnetic drill collar is a type of drill collar designed to avoid interference with magnetic measurement tools and sensors. These collars are made from non-magnetic materials such as specific stainless steels or high-nickel alloys. Non-magnetic drill collars are essential for applications where accurate magnetic readings are critical, such as in measurement while drilling (MWD) and logging while drilling (LWD) operations.

Drill Collar Weight Calculation

Calculating the weight of a drill collar is essential for ensuring that it provides the required support and stability. The weight per foot (ppf) is commonly used, and it can be calculated based on the collar’s dimensions and material density. For example, the weight calculation for a 4 3/4 drill collar involves multiplying its volume by the material’s density.

Drill Collar Specifications Overview

Here’s a summary of typical specifications for spiral drill collars:

Size: Ranges from 4 3/4 inches to 8 inches or more.

Weight: Varies based on size and material, commonly between 100-300 ppf.

Material: High-strength steel or non-magnetic alloys.

Torque Capacity: Determined by the collar’s design and material.

Conclusion

Spiral drill collars play a vital role in modern drilling operations, providing essential weight, stability, and control. By understanding their specifications, types, and functions, you can select the right spiral drill collar to optimize your drilling performance. Whether you need a standard, non-magnetic, or heavyweight drill collar, choosing the appropriate component ensures efficient and reliable drilling operations.

For more information on spiral drill collars, including prices, sizes, and specifications, contact Welleshaft.