Silicon Micro-Machining Manufacturing: Precision at the Microscale

Introduction

In an era defined by technological advancement, the demand for miniaturized, high-precision components has skyrocketed. Silicon, a material long revered for its semiconductor properties, has emerged as a crucial building block in this miniaturization revolution. Enter silicon micro-machining manufacturing – a highly specialized field that manipulates silicon at the microscale to create intricate structures and devices that underpin a vast array of modern technologies. This article delves into the intricacies of silicon micro-machining, exploring its processes, applications, and why choosing the right manufacturing partner, like Welleshaft, is paramount for success.

What is Silicon Micro-Machining Manufacturing?

Silicon micro-machining refers to a set of advanced manufacturing techniques used to fabricate structures, devices, and components from silicon at the micrometer and nanometer scale. It’s distinct from traditional machining, which deals with much larger dimensions, and operates in a realm where precision, accuracy, and material purity are critical. This precision is achieved through techniques that meticulously remove, deposit, or modify silicon atoms to create desired shapes and functionalities.

Key Micro-Machining Processes

Several specialized techniques enable the precise manipulation of silicon at the microscale. These techniques can be broadly classified into two main categories: bulk micro-machining and surface micro-machining.

Bulk Micro-Machining

Bulk micro-machining involves removing material from a silicon wafer to create three-dimensional structures. Key processes include:

-

Wet Etching: This technique uses chemical etchants to selectively remove silicon, creating specific patterns. Etching can be isotropic (etching in all directions) or anisotropic (etching preferentially along certain crystal planes), allowing for the creation of diverse structures.

-

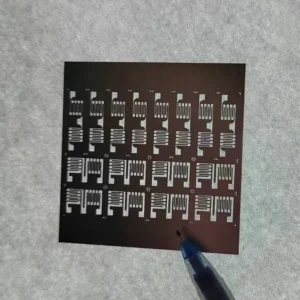

Dry Etching: Dry etching utilizes plasma to remove silicon. It is highly precise and can produce sharper features compared to wet etching. Techniques include Reactive Ion Etching (RIE), Deep Reactive Ion Etching (DRIE), and Ion Beam Etching (IBE).

-

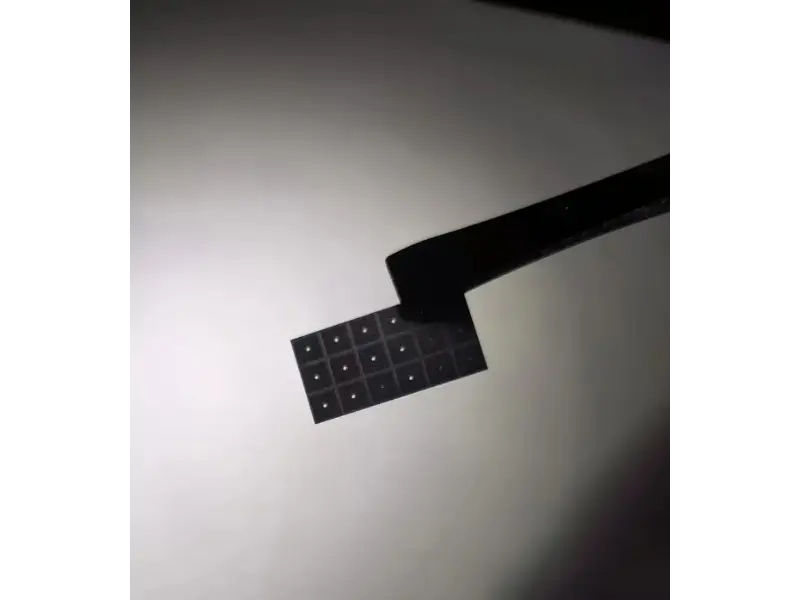

Laser Micromachining: Focused laser beams are used to precisely ablate (remove) silicon material. This process is versatile and can create complex shapes with minimal thermal damage.

-

Mechanical Micromachining: Highly precise cutting tools and abrasive materials are used to remove material mechanically. This process is suitable for creating high aspect ratio features and can handle a wide range of materials.

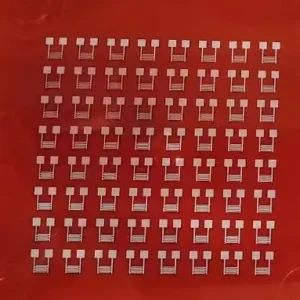

Surface Micro-Machining

Surface micro-machining involves building up structures on the surface of a silicon wafer using thin film deposition and selective etching techniques. Key processes include:

-

Thin Film Deposition: Techniques like Chemical Vapor Deposition (CVD), Physical Vapor Deposition (PVD), and sputtering are used to deposit thin layers of materials on the silicon substrate, which can then be patterned and etched.

-

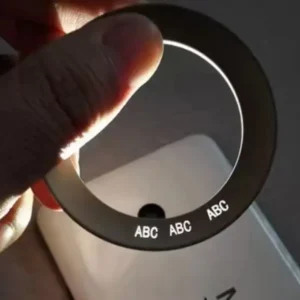

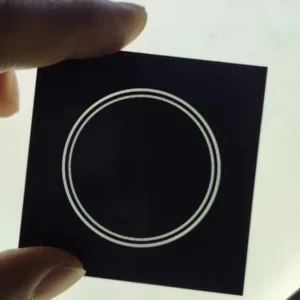

Photolithography: This process involves transferring a pattern from a mask onto the silicon wafer using light-sensitive materials. It is a crucial step for creating intricate features in surface micro-machining.

-

Sacrificial Layer Etching: This technique involves selectively removing certain thin film layers that have been deposited between functional device layers, creating free-standing structures.

Applications of Silicon Micro-Machined Components

Silicon micro-machined components are at the heart of a multitude of technologies and industries. Here are some key applications:

-

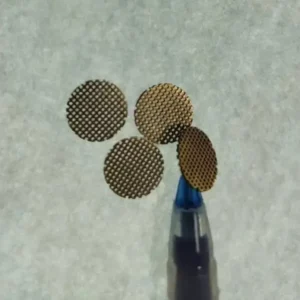

Microelectromechanical Systems (MEMS): MEMS devices utilize micro-machined silicon structures to sense, actuate, or control physical parameters. Examples include:

-

Accelerometers and gyroscopes in smartphones and automotive safety systems.

-

Pressure sensors in medical devices and industrial equipment.

-

Micro-mirrors in optical communication and displays.

-

-

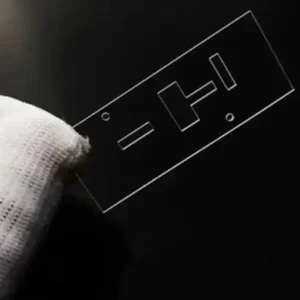

Microfluidics: Microfluidic devices use micro-channels and other silicon structures to manipulate fluids at a microscale. Applications include:

-

Lab-on-a-chip devices for diagnostics and drug discovery.

-

Micro-pumps and valves for fluid control.

-

-

Sensors and Transducers: Micro-machined silicon is used to create high-sensitivity sensors for detecting physical, chemical, and biological signals. Examples include:

-

Temperature and humidity sensors.

-

Gas sensors for environmental monitoring.

-

Biosensors for medical and life science applications.

-

-

Optical Devices: Micromachined silicon is used to create components such as optical gratings, waveguides, and micro-lenses.

Challenges in Silicon Micro-Machining

Silicon micro-machining is not without its challenges. Key factors that require careful management include:

-

Precision and Accuracy: Achieving nanometer-scale precision requires highly controlled processes and advanced metrology techniques.

-

Material Purity: Silicon must be extremely pure to avoid defects that can impact device performance.

-

Surface Finish: Controlling the surface roughness and topography of micro-machined silicon is essential for many applications.

-

Cost of Production: The complexity and precision required in silicon micro-machining can lead to higher production costs.

-

Integration and Packaging: Integrating micro-machined devices with other components and packaging them for real-world applications can be a complex process.

The Importance of a Reliable Manufacturing Partner: Welleshaft

When it comes to silicon micro-machining manufacturing, choosing a partner with the right experience, expertise, and facilities is crucial. Welleshaft stands out as a trusted global supplier and contract manufacturer with a proven track record in precision manufacturing.

Why Choose Welleshaft for Silicon Micro-Machining?

-

Expertise and Experience: Welleshaft possesses a deep understanding of silicon micro-machining processes, material properties, and application requirements.

-

State-of-the-Art Facilities: They have invested heavily in advanced equipment, including cleanrooms, photolithography tools, dry and wet etching systems, laser micro-machining capabilities, and thin-film deposition systems.

-

Custom Solutions: Welleshaft offers custom design and engineering services, working closely with clients to develop solutions that meet their specific needs.

-

Quality Assurance: They implement rigorous quality control measures at every stage of the manufacturing process to ensure the highest standards of precision, reliability, and repeatability.

-

Global Supply Chain: Welleshaft has a strong global presence, enabling them to efficiently and effectively serve clients around the world.

-

Contract Manufacturing Services: Welleshaft also provides contract manufacturing services, allowing you to outsource your production needs while maintaining the highest levels of quality.

-

Commitment to Innovation: Welleshaft continuously invests in new technologies and techniques to push the boundaries of micro-machining and deliver cutting-edge solutions.

Information Table for Reference

Here is a summary table of key silicon micromachining processes, materials, applications and challenges:

| Category | Process/Material | Description | Applications | Key Challenges |

| Bulk Micro | Wet Etching | Chemical removal of silicon. Isotropic or anisotropic. | Simple structures, microchannels | Controlling etch rate, undercutting |

| Dry Etching (RIE, DRIE, IBE) | Plasma-based removal of silicon for precise features. | High aspect ratio features, complex patterns, MEMS fabrication | Controlling sidewall profile, etch uniformity | |

| Laser Micro-Machining | Removal of silicon with focused laser beam. | Versatile shaping, high aspect ratio features, fast prototyping | Thermal damage, debris control | |

| Mechanical Micro-Machining | Material removal via precision cutting tools and abrasives. | High aspect ratios, high precision features | Tool wear, debris control | |

| Surface Micro | Thin Film Deposition (CVD, PVD) | Adding thin layers of various materials on the silicon substrate. | Multilayer devices, sensors, optical devices | Material uniformity, interface control |

| Photolithography | Pattern transfer via light-sensitive layers and masks. | Feature creation for thin film structures, micro-circuit creation | Mask alignment, feature size control | |

| Sacrificial Layer Etching | Selectively removing deposited layers to create suspended structures | MEMS devices, cantilevers, resonators | Controlling release etch, stiction | |

| Material | Silicon (Mono/Poly) | Primary substrate material. High purity and suitable electronic properties. | Primary material for MEMS, microfluidics, optical devices, sensors, electronic devices | Material purity, processing difficulty |

| Applications | MEMS (Sensors, Actuators) | Micro-devices that sense, actuate, or control physical parameters | Accelerometers, gyroscopes, pressure sensors, micro-mirrors | Complex packaging, reliability |

| Microfluidics | Devices to manipulate fluids at microscale | Lab-on-a-chip diagnostics, micro-pumps, valves | Channel clogging, fluid interface control | |

| Optical Devices | Components for manipulating light at micro-scale. | Optical gratings, waveguides, micro-lenses, micro-mirrors | Alignment accuracy, surface smoothness |

Conclusion

Silicon micro-machining manufacturing is a complex and demanding field that is vital for driving progress in numerous industries. As the demand for ever-smaller and more precise devices continues to grow, the need for reliable and expert manufacturing partners becomes increasingly important. Welleshaft’s dedication to quality, innovation, and customer satisfaction makes them a premier choice for businesses seeking to harness the power of silicon micro-machining. By partnering with Welleshaft, you gain access to cutting-edge technology, experienced engineers, and a commitment to producing high-quality, customized components that meet your specific needs and drive your success.

Reviews

There are no reviews yet.