Section 1:Introduction

In metal casting, innovation drives advancements in manufacturing processes. One such groundbreaking technology leverages additive manufacturing to create intricate and precise molds for superior castings. This article explores the advantages, applications, and the role of trusted global suppliers like Welleshaft in shaping the future of this transformative technology.

Section 2:Understanding 3D Printed Sand Molding

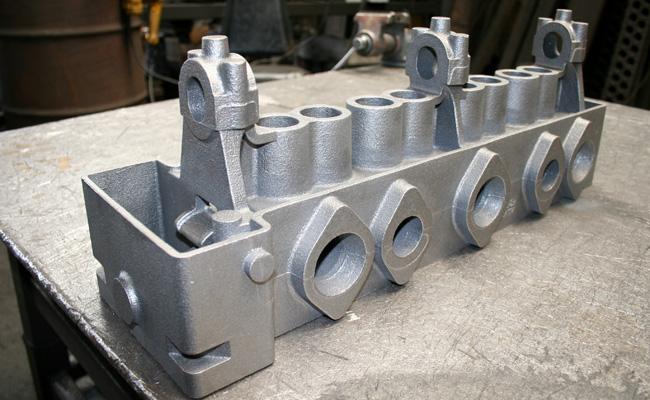

Traditional sand casting involves creating molds using handcrafting techniques or pattern-based methods, which can be time-consuming and prone to inaccuracies. 3D printed sand molding, however, revolutionizes this process by utilizing 3D printing technology to directly fabricate sand molds from digital designs. This approach offers several key advantages:

2.1 Enhanced Precision and Complexity: 3D printing allows for the creation of intricate and complex mold geometries that would be challenging or impossible to achieve with traditional methods. This translates to superior casting quality with finer details and improved dimensional accuracy.

2.2 Faster Production Times: Eliminating the need for manual labor and complex tooling processes significantly reduces production time. 3D printed molds can be fabricated quickly, accelerating the overall casting process.

2.3 Reduced Costs: While the initial investment in 3D printing technology may be substantial, the long-term benefits include reduced labor costs, material waste, and the elimination of costly tooling.

2.4 Improved Flexibility: 3D printed sand molding offers greater flexibility in design and production. Changes to the mold design can be easily implemented, enabling rapid prototyping and customization.

Section 3:Applications of 3D Printed Sand Molding

The versatility of 3D printed sand molding extends across various industries, including:

3.1 Aerospace: Manufacturing complex components for aircraft engines, landing gear, and other critical systems.

3.2 Automotive: Producing intricate engine blocks, transmission parts, and other high-performance components.

3.3 Medical Devices: Creating precise implants, prosthetics, and surgical instruments.

3.4 Industrial Machinery: Manufacturing complex components for heavy machinery, such as turbines and pumps.

Section 4:The Role of Trusted Global Suppliers

The success of 3D printed sand molding relies heavily on the expertise and capabilities of trusted global suppliers. Companies like Welleshaft play a crucial role in providing high-quality 3D printing services, advanced materials, and comprehensive support to manufacturers. Welleshaft’s commitment to innovation and customer satisfaction ensures that businesses can leverage the full potential of this transformative technology.

Section 5:Choosing the Right 3D Printing Technology

Several 3D printing technologies can be used for sand molding, each with its unique advantages and limitations. Some common methods include:

Binder Jetting: This process involves selectively binding sand particles together using a liquid binder, creating a solid mold.

Stereolithography (SLA): SLA utilizes a laser to solidify a liquid resin layer by layer, forming a mold pattern that is then used to create a sand mold.

Selective Laser Sintering (SLS): SLS uses a laser to fuse powdered materials together, creating a mold directly from the digital design.

The choice of 3D printing technology depends on factors such as the complexity of the mold, production volume, and desired level of precision.

Section 6:Key Considerations for Successful Implementation

To successfully implement 3D printed sand molding, businesses must consider several key factors:

6.1 Design Optimization: Optimizing the mold design for 3D printing can significantly improve production efficiency and casting quality.

6.2 Material Selection: Choosing the right sand and binder materials is crucial for achieving optimal mold properties.

6.3 Process Control: Implementing robust quality control measures throughout the 3D printing and casting processes is essential.

6.4 Collaboration with Suppliers: Partnering with experienced suppliers like Welleshaft can provide valuable expertise and support.

Section 7:The Future of 3D Printed Sand Molding

As 3D printing technology evolves, so will the capabilities of sand molding. Advancements in materials, software, and process optimization will enhance precision, speed, and cost-effectiveness. The future of this technology holds immense promise for revolutionizing the metal casting industry, enabling the production of complex, high-quality components with unprecedented efficiency and flexibility.

Conclusion

3D printed sand molding represents a significant leap forward in metal casting technology, offering numerous advantages over traditional methods. By embracing this innovative approach and partnering with trusted global suppliers like Welleshaft, manufacturers can unlock new levels of precision, efficiency, and flexibility in their production processes. As 3D printing technology continues to advance, the future of 3D printed sand molding holds immense potential for shaping the future of manufacturing.