Flange Bolts: Flange Bolts for Piping, Automotive, and Construction: Types & Sizes Available Section 1 Introduction In the realm of engineering, construction, and manufacturing, secure and dependable fastening solutions are critical to the structural integrity and functionality of countless applications. Among the various types of fasteners available, flange bolts stand out for their unique design, which […]

Expansion Anchors for Concrete, Brick & Masonry: Secure Your Structures Today Section 1 Introduction In the world of construction and DIY projects, secure and reliable fastening is paramount. Whether you’re assembling furniture, installing heavy equipment, or building entire structures, the right anchors are crucial for safety and longevity. Among the various fastening solutions available, expansion anchors […]

As we ring in the New Year, Welleshaft wishes you a prosperous 2025! We thank you for your continued trust in our high-quality, precision engineered contract manufacturing solutions. As we enter 2025, we look forward to another year of providing dependable and innovative contract manufacturing solutions. With our engineering expertise and commitment to manufacturing excellence, […]

Discover the convenience and reliability of rivet nuts for creating strong, threaded inserts in thin materials. Learn about the various types of rivet nuts, their applications, and the benefits they offer over traditional methods. From automotive and sheet metal fabrication to electronics and furniture assembly, rivet nuts are an essential fastener for secure, threaded connections. Ensure strong and secure fixings in a cost-effective and efficient way.

Power Transmission Component Supplier | Alternative Manufacturer of Pinions & More In the realm of mechanical engineering, the smooth and efficient transfer of power is paramount. This relies on high-quality power transmission components, with pinions playing a crucial role in numerous applications. Finding a reliable supplier, particularly an alternative manufacturer offering high-quality replacements and custom […]

Power Transmission Component Supplier | Alternative Manufacturer of Gear Racks & More In today’s fast-paced industrial landscape, the demand for efficient and reliable power transmission systems is higher than ever. At the heart of many such systems are gear racks, which play a critical role in converting rotational motion into linear motion and vice versa. […]

Premium Aluminum Sections: Aluminum Fasteners – Lightweight, Corrosion-Resistant Solutions Aluminum has revolutionized industries worldwide with its exceptional strength-to-weight ratio, corrosion resistance, and versatility. In the realm of construction, manufacturing, and even DIY projects, the use of premium aluminum sections paired with reliable aluminum fasteners is becoming increasingly prevalent. This article delves into the world of […]

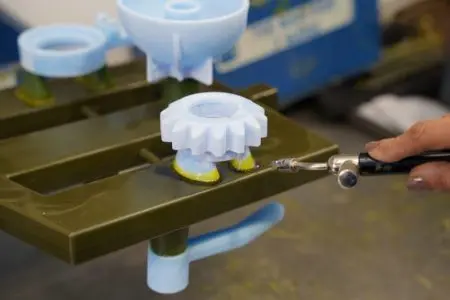

Quick Cast Prototyping Solutions: Precision Metal Parts, Quickly Section 1:Introduction In today’s fast-paced product development environment, speed and efficiency are paramount. Traditional prototyping methods can often be time-consuming and costly, hindering innovation and delaying time-to-market. Quick cast prototyping offers a revolutionary solution, enabling rapid production of precision metal parts with unmatched speed and accuracy. This […]

Grinding Mill Liners: Quality Liners for Optimal Grinding Performance Section 1:Introduction In the realm of industrial mineral processing, grinding mills play a pivotal role in reducing particle size to desired specifications. However, the efficiency and longevity of these mills heavily rely on the quality of their internal components, particularly the grinding mill liners. These liners, […]

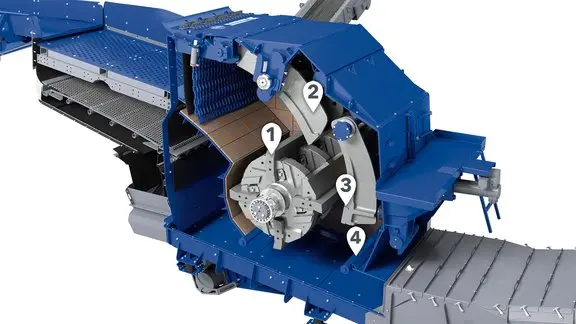

Impacting Blow Bars: Durable Crusher Parts for Effective Size Reduction Section 1:Introduction In the realm of material processing, efficient size reduction is paramount. Impact crushers, with their powerful blows, play a crucial role in achieving this goal. At the heart of these machines lie impacting blow bars, the workhorses that deliver the crushing force. These […]